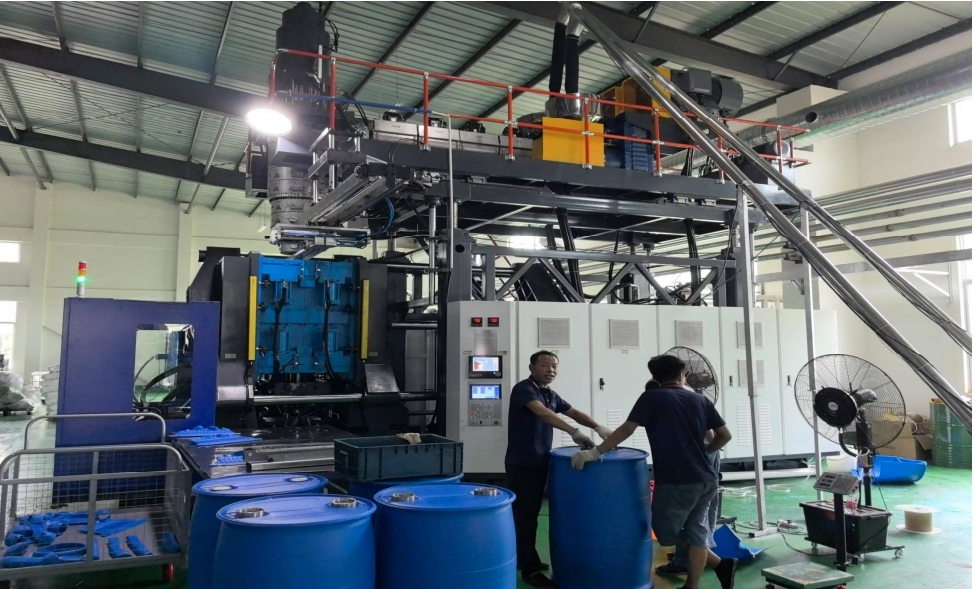

Machine model: EJB120N

Machine matched die head: Accumulator type

Machine capacity:200L

Delivery Time: 75 working days

30L- 200L Automatic plastic jar hdpe drum blow moulding making machine

Our 30L, 60L, 100L, and 200L plastic barrel blow molding machines are designed to meet the demand for producing high-quality, large-capacity plastic containers. These machines are widely used in industries such as chemical storage, oil containers, industrial packaging, and agriculture. Leveraging advanced technology and high production efficiency, our blow molding machines ensure each barrel is manufactured with precision and durability. These machines are capable of producing large-capacity containers requiring high strength and durability. Equipped with advanced wall thickness control, these machines ensure the production of high-quality plastic barrels with uniform wall thickness and high strength. Whether used for storage, transportation, or industrial applications, our machines provide the optimal solution for large-scale plastic barrel production.

Precise Control for Improved Production Efficiency

Our microcomputer control system provides real-time data and allows for precise adjustment of key parameters such as temperature, pressure, and time. This ensures an optimized production process, minimizes waste, and maximizes output efficiency. The automated production line and intelligent control system also reduce operator intervention and improve overall efficiency, making it an ideal choice for high-volume plastic barrel production.

Powerful air pressure system ensures precise barrel shaping. The air pressure system is a key feature of our blow molding machines, especially when producing large plastic containers such as 30L, 60L, 100L, and 200L barrels. Our machines utilize a high-performance air pressure system to ensure uniform air distribution and precise shaping of each barrel. This system ensures uniform barrel wall thickness and consistent shape, which is crucial for storing and transporting liquids and chemicals.

The machine utilizes an energy-saving servo motor, significantly reducing the production cost of plastic barrels.

Suitable for a variety of industries:

Chemical and industrial packaging: For the safe storage and transportation of chemicals, oils, and other hazardous materials.

Food storage: For bulk packaging of food, particularly in industries requiring large-capacity containers.

Agricultural applications: For the storage and transportation of fertilizers, pesticides, and other agricultural liquids.

MACHINE PARAMETER

| Accumulator die head blow molding machine | ||||

| Accumulator type | EJB80N-30L | EJB90N-60L | EJB100N-120L | EJB120N -200L |

| Parameters | ||||

| Max die capacity | 3.5L | 5L | 12L | 25L |

| Max die pin diameter | 300mm | 350mm | 450mm | 600mm |

| Screw diameter | 80mm | 90mm | 100mm | 120mm |

| Screw L/D ratio | 24 | 24 | 24 | 28 |

| Screw RPM(50HZ) | 10-60 r/min | 10-60 r/min | 10-60 r/min | 10-50 r/min |

| Extrusion capacity per hour(PE) | 110kg/h | 140kg/h | 180kg/h | 320kg/h |

| Number of heaters | 4 | 4 | 5 | 6 |

| Platen size | 750mm x 800mm | 900mm x950mm | 1050mm x1260mm | 1400mm x1600mm |

| Clamping stoke | 450mm-1000mm | 450mm-1100mm | 500mm-1300mm | 600mm-1800mm |

| Clamping force | 230KN | 360KN | 440KN | 1700KN |

| Dry cycle time | 13S | 13S | 15S | 15S |

| Cooling water pressure | 0.2-0.3MPa | 0.2-0.3MPa | 0.2-0.3MPa | 0.2-0.3MPa |

| Cooling water consumption | 60L/min | 80L/min | 100L/min | 300L/min |

| Air pressure | 0.8MPa | 0.8MPa | 0.8MPa | 0.8MPa |

| Compressed air consumption | 0.8m³/min | 1.0m³/min | 1.2m³/min | 2.0m³/min |

| Machine dimension(L x W x H) | 5000x2800x3900mm | 5500x2950x4200mm | 6500x3100x5000mm | 6850x3100x3300mm |

| Machine net weight | 12T | 13.5T | 16T | 28T |

| Power consumption parameter | ||||

| Inverter motor | 30kw | 37kw | 45kw | 90kw |

| Extruder heating power | 16kw | 21.4kw | 25.1kw | 32kw |

| Power of die heating zone | 6kw | 7.5kw | 9.2kw | 15kw |

| Wall thickness hydraulic motor | 4KW | 4KW | 4KW | 7.5KW |

| Hydraulic motor | 13kw | 15kw | 18.5kw | 37kw |

| Maximum Electrical power rating | 69kw | 85kw | 102kw | 182kw |