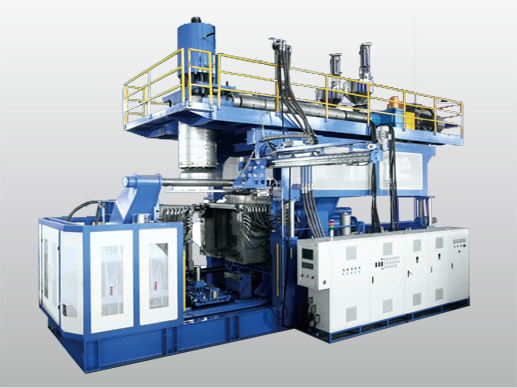

Machine model: EJB1000L

Machine matched die head: Accumulator type, single layer or double layer

Machine capacity:1000L

Delivery Time: 100 working days

IBC tank blow molding machine

The EJB-1000L extrusion blow molding machine is specifically designed for producing large IBC plastic containers (IBCs) ranging from 200 to 1000L. This machine utilizes a specially designed screw structure suitable for high-molecular-weight, high-density polyethylene (HMW-HDPE) materials. It boasts high plasticizing efficiency and stable temperature control, enabling rapid and uniform parison extrusion, effectively improving container molding efficiency and enabling daily production of over 500 pieces.

The machine is equipped with a multilingual touchscreen and Mitsubishi PLC control system. It utilizes internationally renowned components such as a Japan MOOG wall thickness servo control system, a Taiwan YUKEN hydraulic power unit, and an Italy GEFRAN motion module. It offers reliable performance, intelligent operation, and adaptability to continuous production requirements.

1000-liter IBC plastic containers are widely used for the storage and transportation of industrial raw materials and liquid chemicals. Compared to traditional packaging, these containers offer improved space utilization and stacking stability. They are also recyclable, reducing packaging costs. We can also produce multi-layer containers according to demand. The outer layer can use different colors such as black or white to block ultraviolet rays or distinguish uses, while the inner layer maintains clean material to ensure that the contents are not contaminated, meeting the packaging standards of various industries.

Features and Advantages of IBC Blow Molding Machines

IBC blow molding machines are suitable for producing IBC containers of various capacities, including 500L, 800L, 1000L, and 1200L. These IBC containers are widely used in the chemical, filling, and transportation industries. Utilizing German technology and precision mechanical design, the IBC blow molding machine ensures superior reliability and performance. It can operate continuously year-round, 24/7, to meet customer order demands.

Thanks to the trust of our customers, we have delivered over 70 IBC blow molding machines to domestic and international markets.

High Output: 600 IBC containers with 14kg inner liners can be produced per day.

IBC Tonnage Blow Molding Machine: The IBC tonnage extrusion blow molding machine can produce IBC tonnages of various capacities, ensuring uniform thickness and passing drop and vibration tests.

IBC TANK Blow Molding Mold: The IBC tonnage mold is made of high-hardness aluminum alloy material and equipped with an advanced cooling system to ensure a high output of 25 tonnages per hour.

IBC tank HDPE Blow Molding Machine Specifications

|

Extruder |

|

||

|

1 |

Screw diameter |

120mm *2 |

|

|

2 |

L/D ratio |

30:1 |

|

|

3 |

Screw speed |

50-90 r.p.m. |

|

|

4 |

Drive motor |

110Kw *2 |

|

|

5 |

Inverter drive |

DELTA |

|

|

6 |

Plasticizing ability |

800kg/h (plastic special for IBC) |

|

|

7 |

Heating zone with cooling fan |

5 zones |

|

|

8 |

Heating capacity |

9kw *5*2 |

|

|

9 |

Fan power |

550w *5*2 |

|

|

10 |

Vertical adjustment of head |

800mm |

|

|

DIE HEAD |

|

||

|

1 |

Accumulator capacity |

IBC special use |

|

|

2 |

Design |

First in, first out |

|

|

3 |

Heating zone |

8 zones |

|

|

4 |

Heating capacity |

81.6 kw(die head+ connecter+ flange) |

|

|

5 |

Max die pin diameter |

950 mm |

|

|

6 |

Die head axis with pre-blow |

¢160mm |

|

|

CLAMPING UNIT |

|

||

|

1 |

Tie bar |

Two tie bar |

|

|

2 |

Platen size |

1600(W)X 1600(H) |

|

|

3 |

Thicknes of mold |

1200mm |

|

|

4 |

Clamping force |

2000KN |

|

|

5 |

Close/Open stroke |

1200-2600 mm |

|

|

6 |

Mold size |

1500*1500mm |

|

|

7 |

Number of hydraulic cylinder |

1 |

|

|

8 |

High pressure |

14mpa |

|

|

PNEUMATIC SYSTEM |

|

||

|

1 |

Operate pressure |

0.7 mpa |

|

|

2 |

Blow pressure |

0.6 mpa |

|

|

3 |

Needle blow circuit |

High & Low pressure Controlling |

|

|

PARISON CONTROL |

|

||

|

1 |

Programmer |

MOOG 100 points Japan |

|

|

2 |

Servo cylinder |

Belong to the die head |

|

|

3 |

Servo valve |

MOOG Japan |

|

|

ELECTRICITY |

|

||

|

1 |

Contactor |

OMRON |

|

|

2 |

Total connected load (approx.) |

430 KW |

|

|

3 |

Average energy consumption (approx.) |

180 kw |

|

|

WATER COOLING |

|

||

|

1 |

Machine water consumption |

4500L/hr |

|

|

2 |

Mold water consumption |

3000L/hr |

|

|

Others |

|

||

|

1 |

Compressed air consumption |

1000 m³/hour(pressure 8kg/cm) |

|

|

2 |

Alarm for thermocouple and heating element breakage |

fixed alert, Ammeter observing(Optional parts) |

|

|

3 |

Pre-heating function |

fixed |

|

|

4 |

Machine Dimension |

8.8×6.5×6.1(L×W×H) |

|

|

5 |

Total weight |

60 T |

|

|

The EJB1000L-2 fully automatic double-layer IBC blow molding machine is designed for producing 500-1000L IBCs (medium-sized bulk containers). This IBC blow molding machine can produce 500L, 800L, 1000L, and 1200L IBCs, with single-layer, double-layer, and triple-layer structures available.

|

|||