PLASTIC HDPE DETERGENT BOTTLE BLOW MOLD

We can customize blow molds based on your plastic product design or sample.

Blow Mold materials can be P20 steel, S136 stainless steel, 7075 or 6061T aluminum, and the cutouts can be inlaid with stainless steel or beryllium copper.

Blow Mold dimensions are designed to meet the opening and closing dimensions of your blow molding machine.

Blow Mold cavities can be customized based on your extrusion blow molding machine's die head specifications.

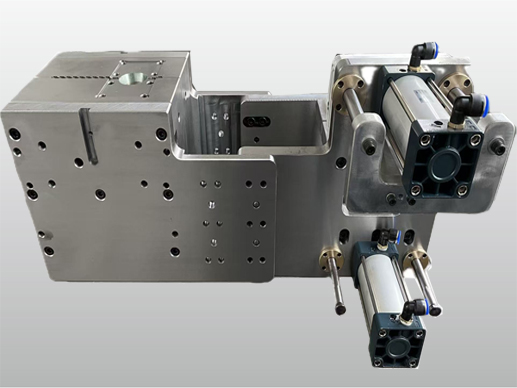

Automatic deflashing molds can be designed to meet your extrusion blow molding machine's die stroke. We use aluminum for the deflashing and anodize it. The secondary mold is smooth and rounded, ensuring scratch-free plastic products.

Our custom blow mold process is as follows:

1. The customer provides us with a product design idea or a plastic sample. Our engineers create a product drawing that meets your requirements, including dimensions, volume, logo, and other information. We also specify the mold material for each component on the drawing.

2. The customer confirms the 2D and 3D product drawings. 3. We will begin designing the 3D mold drawings and provide them to the customer for final verification.

4. Once the mold is complete, we will produce a sample of the plastic product that meets the customer's weight requirements and wait for the customer to inspect it.

5. Once the customer confirms the final sample, we will wrap the mold with stretch film and package the blow mold in an export wooden box.

6. We will ship the blow mold to the customer by sea or air.