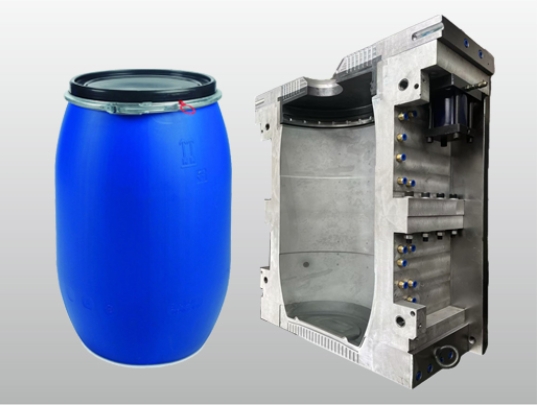

200ltr 220ltr HMW HDPE PLASTIC DRUM OPEN HEAD SINGLE RING BLOW MOULD,BLOW MOLD

We specialize in the design and manufacture of high-performance blow molds for HMW HDPE (high molecular weight, high density polyethylene) plastic open-end drums. These molds can be used to produce a variety of high-standard, high-strength intermediate bulk containers. These chemical drums, with their exceptional chemical and impact resistance, as well as excellent sealing properties, are widely used for the safe storage and transportation of chemical raw materials, food, hazardous materials, and more.

We offer a variety of mold materials to meet diverse budgets:

P20 pre-hardened mold steel: Cost-effective and offering excellent overall mechanical properties, it is a popular choice for large-scale production.

Aluminum alloy molds: Extremely lightweight and offering excellent thermal conductivity, they enable ultra-fast cooling cycles, significantly improving production efficiency. They are ideal for customers seeking energy savings, quick mold changeovers, and maximum output.

We understand that efficiency and automation are at the core of modern production. Therefore, our molds are carefully considered and customized with cooling circuits, integrated with the production processes of fully automated blow molding machines. Chemical barrel cooling for the mouth, middle, and bottom sections: Optimized, independent cooling systems significantly shorten molding cycles, accelerate cooling, and ensure uniform and rapid barrel molding, significantly increasing your daily output.

We also offer comprehensive custom design services, from mold to final product. Whether you have specific requirements for barrel capacity, wall thickness, structural strength, stacking configuration, mouth thread specifications, or external markings, our engineering team will work closely with you to transform your ideas into safe, reliable, cost-effective, and high-quality products.

Our custom blow mold production process is as follows:

1. The customer provides a product design concept or plastic sample. Our engineers will create product drawings based on your requirements, including dimensions, volume, markings, and other information. We also specify the mold material for each component on each drawing.

2. The customer confirms the 2D and 3D product drawings. 3. We will begin designing the 3D mold drawing and provide it to the customer for final verification.

4. Once the mold is complete, we will produce plastic product samples that meet the customer's weight requirements and await customer inspection. 5. After the customer confirms the final sample, we will wrap the mold with stretch film and pack the blow mold into an export wooden box.

6. We will ship the blow mold to the customer by sea or air.

We are committed to being your trusted partner with advanced mold technology and comprehensive solutions. We look forward to discussing your specific needs with you.