ABS car spoiler Export to India

The use of fully automatic HDPE extrusion blow molding machines in the plastic packaging industry for detergents and chemicals has significantly improved the production efficiency and product quality of HDPE bottles. These include shampoo bottles, shower gel bottles, detergent bottles, and cleaning agent bottles.

We will discuss the advantages of fully automatic blow molding machines in detergent packaging in five key areas.

a. Extremely High Production Efficiency and Continuity

Unmanned Operation: Once the parameters are set, the machine can run continuously 24 hours a day, requiring only periodic replenishment of raw materials (plastic pellets), significantly reducing manual intervention and downtime.

High-Speed Production: Fully automatic blow molding machines (especially those with multiple die heads) can produce dozens of bottles per minute.

b. Excellent Product Quality and Consistency

Precision Control: A sophisticated PLC (Programmable Logic Controller), servo system, and wall thickness control system precisely control parameters such as temperature, pressure, and blow molding time, ensuring highly consistent wall thickness, weight, and dimensions for each bottle.

c. Excellent Flexibility and Quick Mold Changeover Capabilities

Modular Design: Advanced blow molding machines utilize a quick mold change system, reducing mold and die changeover time to less than half an hour.

Production Parameter Storage: Different plastic bottle production parameters (for different bottle shapes) can be stored. When switching products, simply call up the corresponding parameters, and the system automatically adjusts them, significantly reducing adjustment time and adapting to the trend of small-batch, high-variety production.

d. Significant Cost Savings

Labor Cost: A fully automated production line requires only one or two people for monitoring and auxiliary operations.

Raw Material Cost: The "wall thickness control system" precisely controls the distribution of plastic in different parts of the bottle body, achieving lightweighting while maintaining strength, reducing the amount of raw material used per bottle and directly lowering material costs.

Energy Cost: The blow molding machine utilizes energy-saving servo motors, significantly reducing energy costs.

e. Compliance with Hygiene and Safety Standards

Enclosed Production: Fully automated systems typically feature a closed feeding system, minimizing contact between raw materials and the external environment during production and reducing the risk of contamination.

In addition, Typical Fully Automatic Blow Molding Production Cell Integration

In a chemical and packaging workshop, The fully automatic blow molding machine typically does not operate in isolation but is part of an entire automated packaging production line:

Plastic HDPE Raw Material Feeding System: An autoloader transfers plastic granules from the storage silo to the blow molding machine hopper.

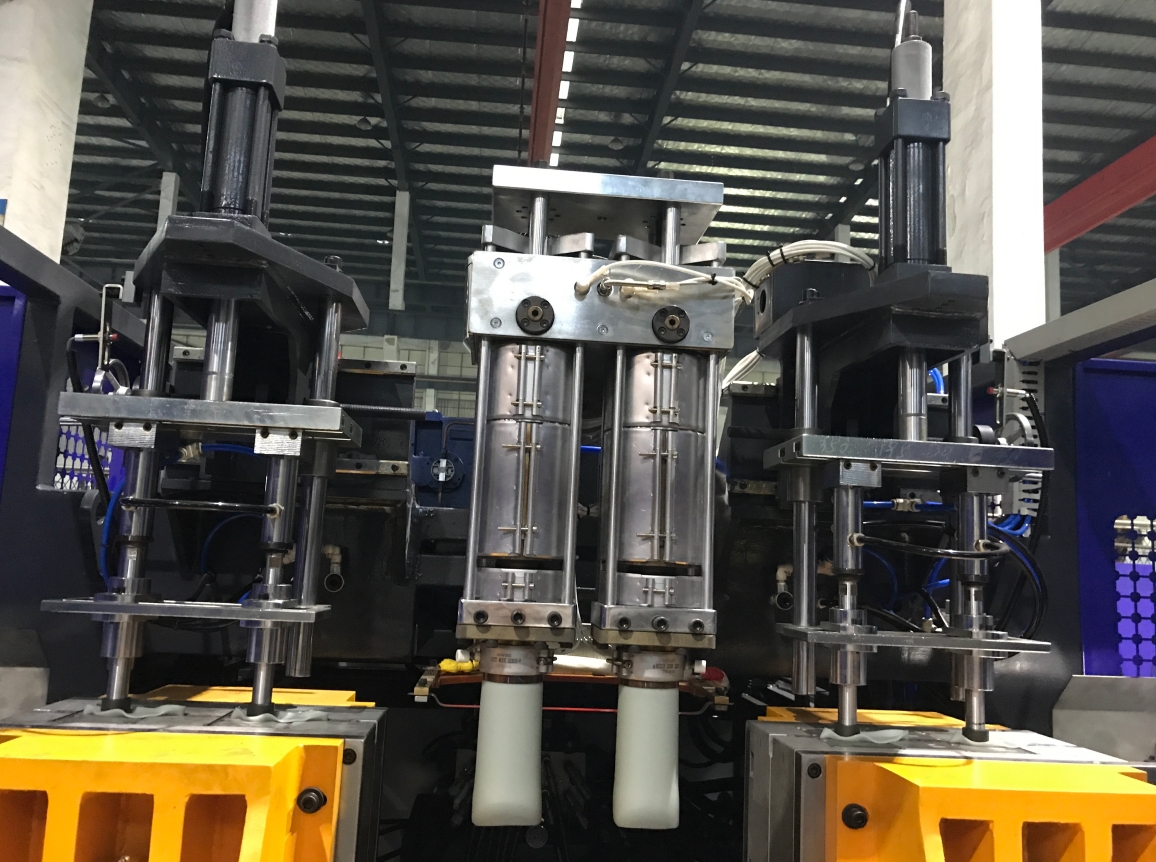

Fully Automatic Blow Molding Machine: Completes the entire process from plasticizing, HDPE Pasion extrusion, mold closing, Blowing air, cooling, and demolding.

Leak Detection System: Automatically detects defects such as bottle neck and body flaws using pressure and automatically rejects defective products.

Auxiliary equipment can be added later:

Labeling Machine: Produced bottles are directly connected to the fully automatic labeling machine via a conveyor belt.

Packer/Palletizer: An automatic baler and palletizing robot are connected at the end of the production line.