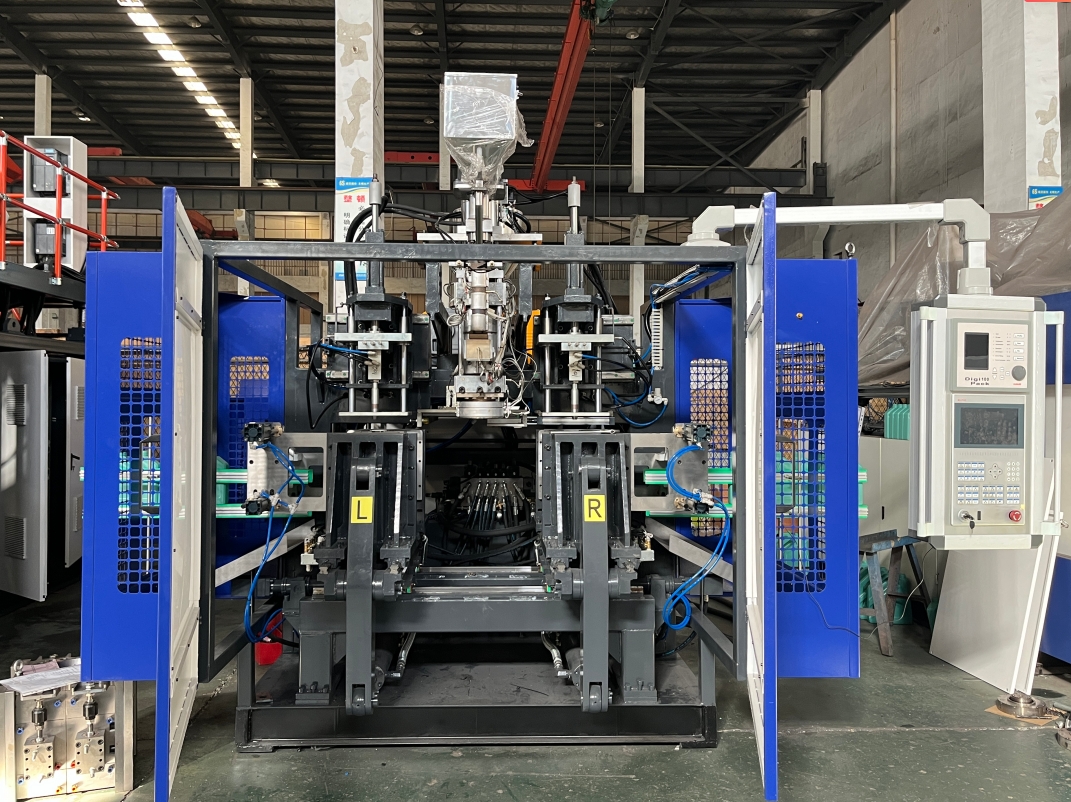

Machine model: EJB70D

Machine matched die head: single double,tri, tetra

Machine capacity:5L

Delivery Time: 40 working days

2L -10L HDPE PLASTIC EXTRUSION BLOW MOLDING MACHINE (EBM)

Our 2L-10L plastic bottle blow molding machines are specialized equipment designed to meet the production needs of medium-sized containers. They are suitable for large-volume packaging in the beverage, daily chemical, pharmaceutical, and industrial product sectors. Combining high-precision control with efficient production capabilities, these machines can consistently process a variety of plastic materials, achieving high-quality blow molding of bottles ranging in size from 2L to 10L.

Specifications and Features

Capacity Coverage:

Small Containers (2L–5L): Commonly used for packaging juice, drinking water, liquid dairy products, as well as household and industrial liquids such as detergents, cleaning fluids, sauces, and car care products.

Medium Containers (5L–10L): Suitable for packaging edible oils, industrial paints, dialysis fluids, lubricants, large-volume detergents, and other commercial or industrial packaging requiring a strong structure and a good seal.

Applicable Models: EJB65S, EJB70D, EJB80S, EJB80D.

Material Compatibility: Compatible with a variety of plastics, including HDPE (chemical resistance, high rigidity), PP (high-temperature resistance, suitable for hot filling), and PVC (high-impact, industrial rigid bottles), meeting the regulatory and functional requirements of food, chemical, and pharmaceutical packaging. Multi-layer co-extruded EVOH high-barrier bottles are also available, suitable for applications such as chemicals and pesticides.Customization and Functional Design: Molds can be customized to meet specific needs, supporting custom-shaped bottle bodies, handle structures, anti-counterfeit bottle necks, and labeling areas. Surface finishes such as glossy, frosted, and embossed finishes are available to enhance brand recognition and packaging quality.

Automation and Intelligent Features:

Integrated modules include automatic loading, in-line inspection, and robotic bottle handling, enabling fully automated production.

Real-time production monitoring and fault diagnosis enhance controllability and maintenance efficiency.

This series of blow molding machines is dedicated to providing customers with reliable solutions for large-volume plastic bottle production, balancing flexibility, efficiency, and quality, meeting the packaging manufacturing needs of diverse markets.

MACHINE PARAMETER

| Continuous extrusion blow molding machine | |||

| Parameters | EJB65S-5L | EJB70D-5L | EJB70S-10L |

| Diameter | 65mm | 70mm | 70mm |

| Screw L/D ratio | 24 | 24 | 24 |

| Screw RPM(50HZ) | 10-80 r/min | 10-60 r/min | 10-60 r/min |

| Extrusion capacity per hour(PE) | 70kg/h | 70kg/h | 70kg/h |

| Number of heaters | 3 | 3 | 3 |

| Opening stoke | 420mm | 420mm | 600mm |

| Platen size | 320mm x410mm | 320mm x410mm | 500mm x540mm |

| Clamping stoke | 150-500mm | 150-500mm | 200mm-650mm |

| Clamping force | 68KN | 68KN | 110KN |

| Dry cycle time | 5S | 7S | 9S |

| Cooling water pressure | 0.2-0.3MPa | 0.2-0.3MPa | 0.2-0.3MPa |

| Cooling water consumption | 50L/min | 50L/min | 60L/min |

| Air pressure | 0.6MPa | 0.8MPa | 0.8MPa |

| COmpressed air consumption | 0.4m³/min | 0.4m³/min | 0.8m³/min |

| Machine dimension(L x W x H) M | 3.4*1.75*2.4 M | 3.4*1.75*2.4M | 3.8*2.1*2.95 M |

| Machine net weight | 5T | 5T | 7T |

| Die head series (Optional) | |||

| Center distance of double-die | 160mm | 160mm | 200mm |

| Center distance of tri-die | 110mm | 110mm | 150mm |

| Center distance of tetra-die | 85mm | 85mm | 100mm |

| Power consumption parameter | |||

| Inverter motor | 18.5kw | 22kw | 22kw |

| Extruder heating power | 13.8kw | 14.2kw | 14.2kw |

| Power of die heating zone | 3kw | 4kw | 4kw |

| Hydraulic motor | 7.5kw | 11kw | 11kw |

| Maximum Electrical power rating | 45.5kw | 55.2kw | 55.2kw |