OUR SUPPLIERS

-

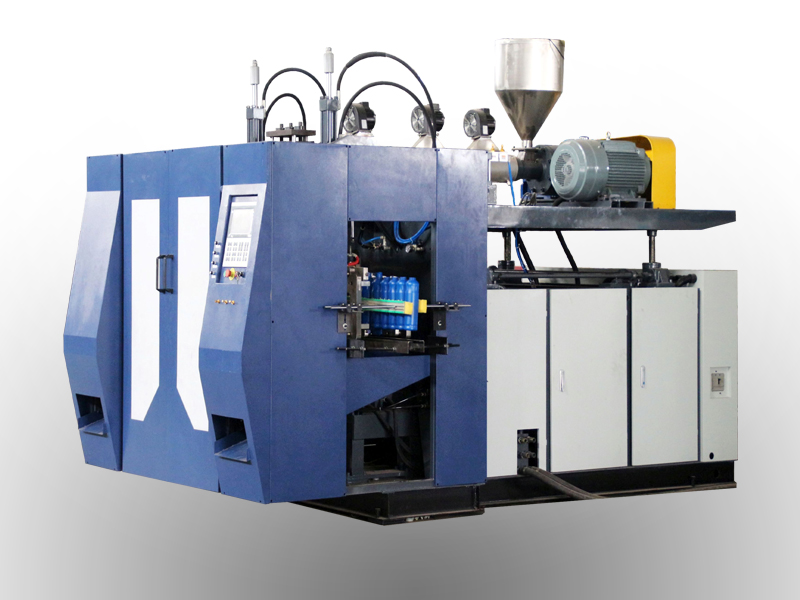

![MOOG Parison Controller]()

MOOG Parison Controller

Achieve precise control of the wall thickness of plastic products, thereby saving raw materials and improving product quality and stability.

-

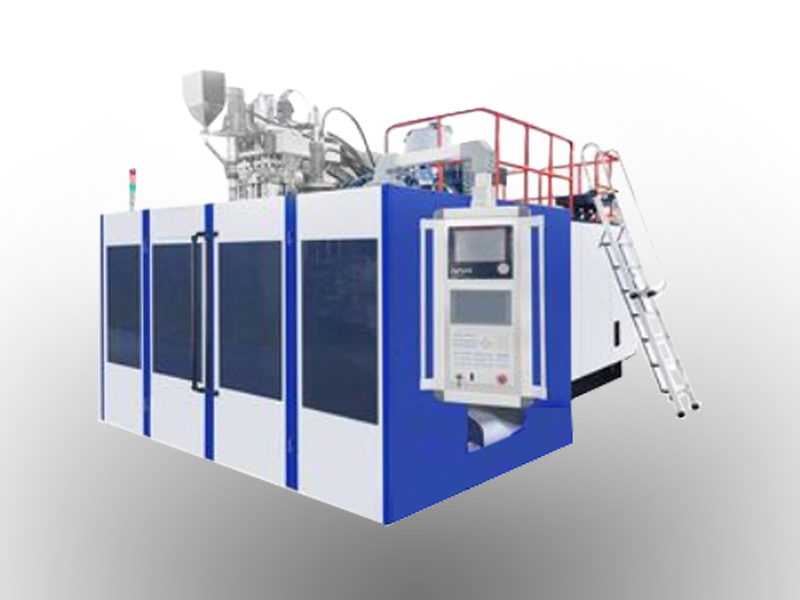

![YUKEN Hydraulic Valve]()

YUKEN Hydraulic Valve

Yuken hydraulic valve is the core component of the hydraulic system of the blow molding machine. It is responsible for accurately and reliably executing mechanical actions such as mold opening and closing, parison extrusion, and mold clamping, ensuring the stability, efficiency, and repeatability of the production process.

-

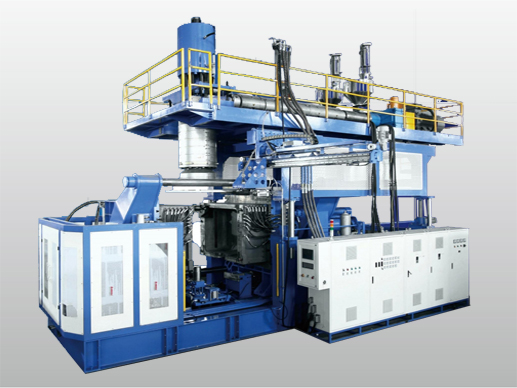

![Mean Well switching power]()

Mean Well switching power

Mean Well switching power supply is the power conversion station of the blow molding machine electrical system, responsible for converting the incoming AC power into various DC low-voltage power in a stable, efficient and safe manner.

-

![AIRTAC Pneumatic components]()

AIRTAC Pneumatic components

AIRTAC pneumatic components are used to perform lightweight and fast actions in blow molding machines, such as picking up parts, conveying, auxiliary demoulding and other secondary actions.

-

![Mitsubishi PLC]()

Mitsubishi PLC

Mitsubishi PLC is the brain of the blow molding machine. It is responsible for receiving signals from various sensors, making judgments, and then issuing instructions to the actuators to direct the various actions of the entire blow molding machine to be carried out in an orderly, automatic and precise manner.

-

![GEFRAN Sensors]()

GEFRAN Sensors

Gefran sensors provide extremely high measurement accuracy for blow molding machines. They measure and provide real-time feedback on the precise position of moving parts, enabling precise control of key processes such as wall thickness control and mold plate movement.